Тестове

Test station

The test station is equipped with test benches for measuring:

І The reagent ingredient efficiency ІІ The efficiency of products /pyrogenerators, anti-hail rockets/ under real conditions. ІІІ The ballistic characteristics of rocket engines.

І Reagent Ingredient Efficiency.

The principle of measuring the efficiency of the ice-forming reagent consists in determining the number of ice crystals which form when introducing a certain amount of the reagent under investigation in the form of an aerosol into a supercooled water mist environment. The mist is created in a cooled cloud chamber by introducing a hot water vapour. The reagent under investigation is used for preparation in advance of an aerosol in a separate chamber (aerosol chamber). The accurately determined portion of the aerosol is introduced into a cloud chamber where the crystals fall to the bottom, on slides. Slides are surveyed and then, the number of crystals is recorded. The minimum and maximum amount of crystals measured according to this method is 107 up to 1019 g-1. The yield of active particles from 1 g of a pyrotechnical composition is determined as per the formula:

N - yield of active particles from 1 g of a pyrotechnical composition; N - average number of crystals obtained from not less than 5 fields of view – the slide area within the lens field of view; V1 - aerosol chamber volume, cm3; S1 - area at the bottom of the cloud chamber, cm2 ( S1= 3.6.103); V2 - aerosol sample volume to be injected into the cloud chamber, cm3; S2 - slide area within the lens field of view, cm2; G - mass of the burnt sample, g

The maximum and minimum value of the total error during the measurement and yield of active particles according to this method is ±30 and ±20%, respectively.

ІІ Efficiency of Products /Pyrogenerators, Anti-hail Rockets/ under Real Conditions.

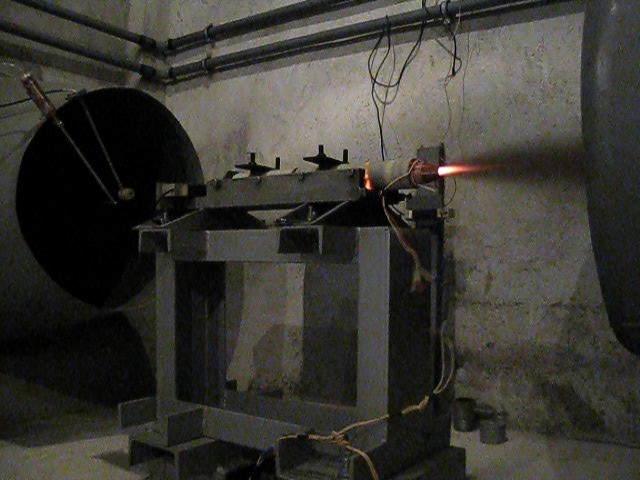

The bench is based on a horizontal streamlined pipe and is intended for measuring the ice-forming activity of aerosols for pyrotechnical generators under real working conditions. The stand is able to simultaneously: https://www.cloud-seeding.info/image/object_image_16.jpg

- measure the ice-forming activity of the aerosol at a rushing flow speed up to 45 m/s; - measure the tractions of generators operating with an ice-forming fuel; - measure the pressure within the generator combustion chamber; - measure the working flow speed, temperature and humidity.

The generator to be tested is positioned within the streamlined pipe flow. The generator aerosol, after even stirring in the pipe tract using elements which cause turbulence falls within the suction pipe diverter of the circulation system, passes along the climatic chamber with supercooled mist and returns back to the pipe tract. The necessary aerosol volume is drawn-in by the system for removal from the circulation system and is introduced into the climatic chamber with supercooled mist.

If the generator to be tested is a high-efficiency one, additional dilution of the aerosol sample is envisaged immediately within the circulation system flow so that overseeding can be avoided. After dosing the aerosol into the climatic chamber, forming and settling the ice crystals, the latter are counted after being surveyed using an electronic microscope. The value of the yield of active cores is calculated as per the following formula:

F – cross-sectional area of the work portion of the streamlined pipe, m2 Sk – area of the climatic chamber bottom, mm2 Sm – area of the microscope field of view, mm2 u – flow speed within the work portion of the streamlined pipe, m2/s m – reagent mass consumption, g/s No – number of ice crystals within the microscope field of view Vo – introduced sample volume

According to our opinion, this method has a number of advantages compared to the conventional tests used for pyrotechnical compositions in micromodel generators. The latter are characterized by:

- impossibility for adequate modelling the work processes in a full-scale generator in case of combustion of the quantity of substance accurately weighed of 0.05 – 0.2 g; - absolute impossibility for correct pressure setting-up when testing ice-forming solid fuels in micromodel generators; - impossibility for taking into consideration processes running when mixing the gas stream (oxidation, coagulation processes) going out of the generator with the atmospheric air.

Based on the huge amount of experimental material obtained during the bench operation, recipes for ice-forming solid fuel have been developed for the thrust parts of “Loza-4/6” rockets which have an increased ice-forming activity. A comparison was made between the results obtained for the generator range for ice-forming aerosol and the test results from similar bench tests of the “Typhoon” scientific-production Association, Russia. https://www.cloud-seeding.info/image/object_image_17.png |

| www.cloud-seeding.info © 2013 |

Website development

|